Tel. +39 0185 773815 - Email: info (@) sateco.it - P.IVA02286910993

ROV components

Pressure Compensators

Pressure compensators are used in all subsea hydraulic systems to negate the effects of pressure differential at depth. The compensation maintains a constant slightly higher oil pressure within the hydraulic system, regardless of depth. It also provides the initial head pressure the hydraulic pump requires for startup without cavitation. Typically around 12 PSI. The design of the compensator ensures this slight over-pressure is maintained for all water depths, from surface to full ocean depth.

Compensators are also used on electrical enclosures to prevent collapse at depth. The enclosure is oil-filled & all air is bled from the system. The compensator is attached to automatically maintain a constant, slight over-pressure, regardless of depth. Typically 5PSI, 10PSI or 15 PSI.

As the internal oil is for all intents & purposes incompressible, this removes the external pressure differential when the enclosure is submerged and prevents enclosure collapse. This method allows lighter, thin wall enclosures to be used, as opposed to heavy thick walled pressure resistant enclosures, thus reducing the overall weight of the equipment.

Also by utilizing a slight over-pressure, this ensures that in the event of a leak, oil will leak out of the system before water is drawn in. Integral measurement transducers, built in to the compensator unit, monitor stroke (leakage) and give for-warning of any problems to the equipment operator, allowing for a timely recovery of the equipment before major damage occurs

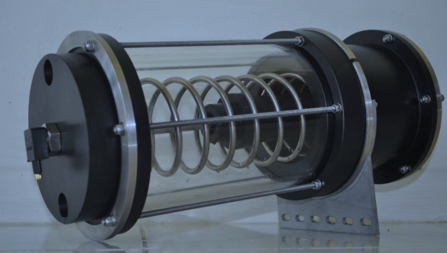

The Clearview style unit. Incorporates the same innovations as the above type, such as SS316 port inserts, linear load rings at the interface between top & bottom cans to avoid distortion & removal of the through bladder hole where the transducer guide rod locates. Available in 2L // 2.7L // 8L // 13L sizes.

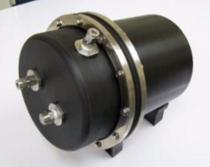

The Perry style unit, with our improvements such as SS316 port inserts, linear load rings at the interface between top & bottom cans to avoid distortion & removal of the through bladder hole where the centralizing rod attaches. Our centralizer screws in to a blind hole in the piston. Available in 1L // 1.5L // 2L sizes

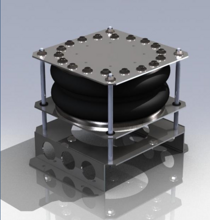

The 18L style unit is of SS316 construction and comes with double convoluted diaphragm. This design is available in 18 to 33L volumes with double or triple convoluted diaphragms, depending upon volume required. Ports arrangements & qty are to user requirement. The unit is available as comp only // magnetic switch transducers (3 positions, user selected) // Linear transducer (analog volts, 4-20mA or RS232 output).

The 100L style unit is of SS316 construction and comes with triple convoluted diaphragm. This design is available in 50L to 100L volumes . Ports arrangements & qty are to user requirement. The unit is available as comp only // magnetic switch transducers (3 positions, user selected) // Linear transducer (analog volts, 4-20mA or RS232 output

Key Features:

Over Pressure Options

Magnetic Switch Sensors Options

Linear Transducer Options

Stainless Steel Mounting Brackets

Number of Ports / Configurations

Relief Valves & Subsea Connectors

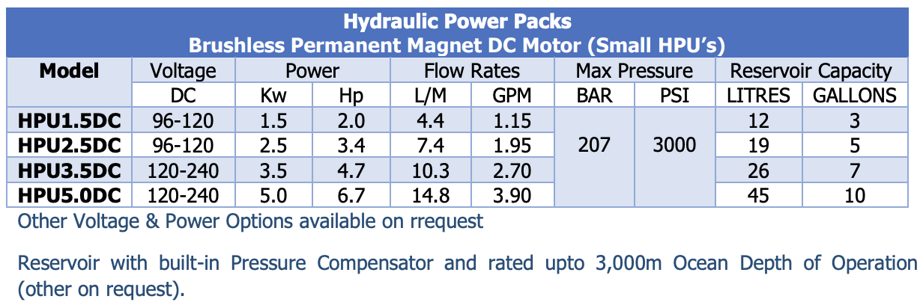

Small Subsea DC & AC Electric / Hydraulic Power Packs

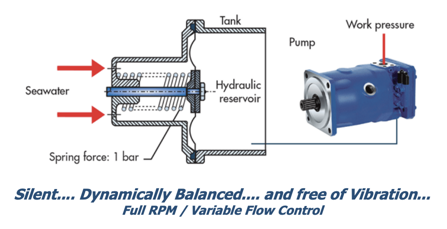

Subsea Permanent Magnet Synchronous Electric / Hydraulic Integrated Power Packs. These robust pressure compensated HPU’s reflect demanding needs on submerged intervention spreads and hydraulic sub-systems. A wide range of variable displacement pumps and regulator options allow tight adaption to application specific requirements. Units are fully self-contained circuit incorporating hyd

Units are fully self-contained circuit incorporating hydraulic pump. Pressure compensated reservoir, suction filter, pressure relief valve and electric motor drives with inlet/outlet connection points

The units operate oil filled and compensated to ambient pressure. The housing is made from machined and anodized aluminum 6082T6. Fasteners, fittings and connectors are made from AISI316 stainless steel.

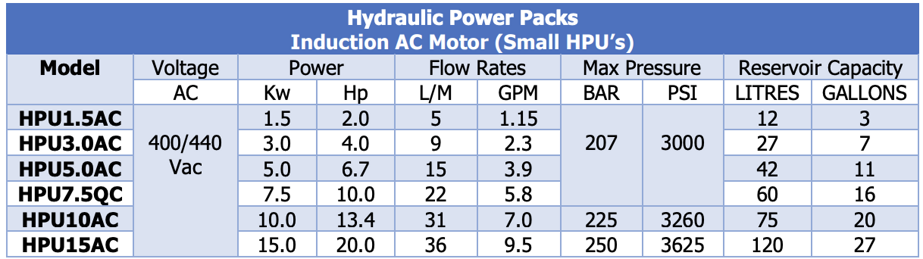

Deep-Sea Pressure Housings

PT. Marine Propulsion Solutions, is a subsea engineering company who designs and manufactures affordable, harsh environment aluminum, stainless steel and Titanium enclosures for housing electrical components to full ocean depth.

MPS’s enclosures are often used for thruster motor controllers, batteries, lights, camera, laser, hydrophones, data-loggers and other sensing and monitoring equipment, instrumentation housings, junction boxes, underwater camera enclosures, general subsea enclosures with internal/external mounting brackets.

We offer multiple families of pressure housings which live up to their pressure rating. which can have many underwater connector interfaces and are used extensively with Remotely Operated Vehicles (ROVs), Autonomous Underwater Vehicles (AUVs) and for many other applications in the oil and gas industry, defense, research, environmental monitoring and offshore renewables.

Tel. +39 0185 773815 - Email: info (@) sateco.it - P.IVA02286910993